You must keep up with the maintenance of your pool. The water is cleaned, kept free of microorganisms, and maintained in a crystal blue color. The skimmer has to be maintained regularly to keep it clear of all the dirt and perhaps even rats that it may accumulate. Maintaining pool equipment and ensuring sure the filter and the pump pressure are effective is a greater effort. What happens if the pool filter pressure drops? How are you even aware that there is a pressure problem? Let's look at how low filter pressure may be diagnosed.

The filter is one of the most crucial components in swimming pool maintenance: Your filtration system keeps the water in your pool sparkling clear and free of contaminants and dangerous microorganisms. It ensures that your chemicals function properly and that your pool water is regulated.

It's a massive task, and the filter of the pool can't do it by itself. You must understand appropriate filter maintenance if you like to maintain your filter performing at its best. Learning to read and comprehend the pressure gauge is one of the most crucial—yet sometimes neglected—aspects of pool filter maintenance.

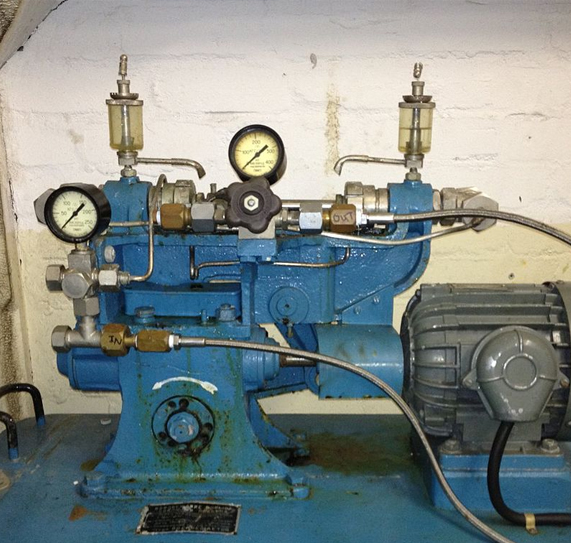

The device that determines how much pressure is accumulating inside your filter is a gauge for the pool filtration pressure. The usual pressure gauge is spherical, has an indication needle, and can read up to 60 PSI.

In general, if the water pressure in your pool filter increases by greater than 10 PSI throughout the typical range, it's time to clean or perhaps replace your filter. 20 or 30 PSI is often regarded as being too high for filters, but you should check with your pool technician to be sure that's the case for your particular model.

Check for filter system leaks if you recently cleaned the filter yet your PSI is still higher than usual.

Having a clog may be the cause of your pressure gauge reading less PSI than usual: If there is any significant debris or obstructions, check the skimmers and all of the filter's lines and remove them. Several other typical reasons why low-pressure issues occur? It's possible that your pump isn't big enough or that the water level in your pool is too low. Check for leaks as well, don't forget. Also causing low pressure, relying on where they are, are holes or leaks.

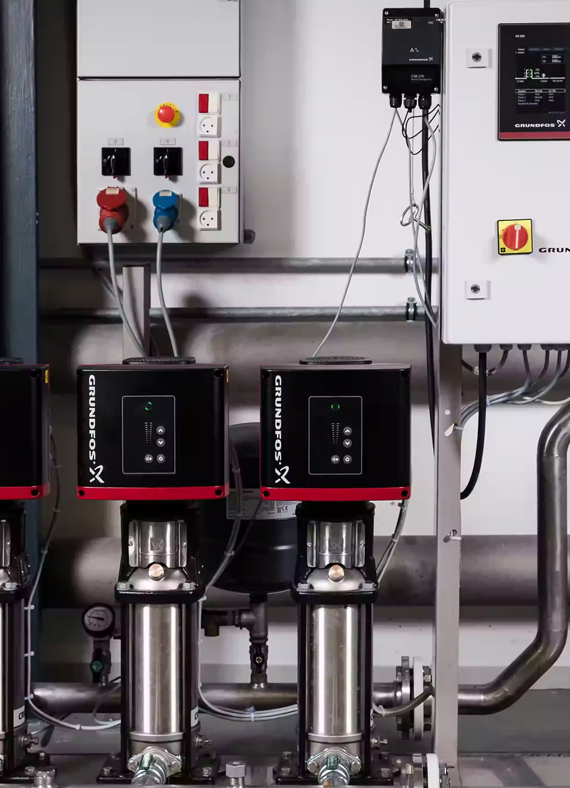

To raise the pressure of water to a desirable level and enhance flow velocity, a pump that boosts is frequently advised. Additionally, they prevent various pumps in the system from caving in situations when a single pump is unable to provide the required service pressure. Learn how and when to utilize booster pumps as a pumping system.

Between the water supply and terminals like showers, and taps, a booster pump serves as a conduit. In order to achieve the appropriate pressure at the endpoints, a booster pump draws water from the origin and pressurizes it.

Typically, there are other tools used in addition to booster pumps to move water inside a system. To raise the fluid pressure, they cooperate with a source pump.

Booster pumps come in very handy in a variety of situations. These pumps can provide the high-pressure head necessary to move water, for instance, through a tall structure or uphill. Due to the high water pressure needed for heavy-pressure spraying devices to operate effectively, a rise in pressure head may also be necessary.

By adding a second pump to the fluid flow system, the booster pump's purpose is to raise the water pressure. As a result, these pumps operate similarly to other pumps.

The majority of them are centrifugal pumps to pump water from a source and pass it through one or more impellers (single-stage or multi-stage) to boost water pressure. After that, the high-pressure water exits through an outlet.

To attain the needed pressure, a pipeline might also have a number of booster pumps installed along it.

For residential structures and standalone homes with moderate pressure requirements, a booster pump (single-stage) is the ideal option. One building usually requires a single-stage booster pump. When there is a very high demand for water pressure, a booster pump (multi-stage) is advantageous. Examples of these uses include raising water uphill or for a neighbourhood with several buildings, maintaining the city's water pressure, and transporting water via a very long pipeline.

Regardless of the sort of pump you pick, you must make sure the pump and filter you choose are the right ones together. In relation to the filter's flow rate, the pump's size must be adequate. The efficiency and life of both the pump and the filter will be shortened if the pump is selected with a flow rate that is higher than the filters.

Water is sucked directly into the submersible pump through a suction grid that is connected to the bottom. The delivery connection, via which the water can exit the pump, is reached after the water has been conveyed through the pump body. A discharge tube or hose is connected to the delivery connection to allow for the drainage of the water. Because it regulates itself with the fluid it pushes, the pump may be submerged partially or entirely. Running dry will harm a submersible pump as a result.

Because of this, no submersible pump can drain a surface totally dry while operating in automatic mode (with a float), although certain types can when operating in manual mode. When they drain, only a few droplets need to be wiped up. It is, in theory, the most basic model available. When the float is triggered, the pump starts working once the hose is put onto it and the plug is plugged into the socket.

The many submersible pump types are easily adaptable to the water/fluids that need to be pushed. There may be circumstances that make water to drain challenging, but there is typically a solution. A submersible puddle pump, for instance, is ideal for the task if an area needs to be entirely dried out. Sometimes the size of these places is quite constrained, thus unique internal floats have been designed to allow the pump to keep running on its own. Additionally, these pumps have been made compact so they may fit in a sump pit.